Used equipment and know-how for rubber molding for sale in Germany

A German company is currently selling its used rubber pressing and molding equipment, as well as technology for manufacturing molded products from recycled tire rubber. The company specializes in the manufacturing of rubberized surfaces for equestrian applications, rubberized flooring solutions and other relevant merchandize.

The reason for equipment and know-how sale is retirement of the company’s owner. The manufacturer aims to alter its business model and focus on project consulting and project support in the field of equestrian riding arena construction.

Goals of the asset deal

- Sale of entire or part of the Intellectual Property on the production machines redesigned or built by the company.

- Sale of all or part of the production machinery.

- Sale of all or some of molds, tools and auxiliary equipment for the production of various pressed rubber goods.

- Depending on the deal, customer contacts may also be sold.

Technology of rubber presses

Thanks to the company’s experience in the field of hydraulics, the presses have a very high pressing force – up to 3,000 tons. Two of the company’s presses were completely designed and built in-house. Due to the semi-automatic production, even products with large dimensions can be manufactured in large quantities.

Advantages of the presses:

- Very high pressing force

- Semi-automatic production

- Company’s products successfully established on the market

- Transfer of know-how and expertise to the buyer

- The system can be adopted for further production lines

Equipment list

The offer includes the following equipment listed below:

Rubber presses

Rubber Press I

Built in 1993, with a base body made by Sack und Kiesselbach (Germany), improved with additional hydraulic cylinders, sliding table, SPS control of feeding system and ejectors

Specifications:

- Oil-hydraulic under-piston production press, with 5 cylinder under-piston pressing unit.

- Continuous pressing force approx. 2500 tons

- Base body made by Sack & Kiesselbach

- Upper and lower pressure plate reinforced

- 2 cylinders for rapid feed

- SPS control with switch and control cabinet

The press comes with:

- 4 x molding boxes, 1.50 x 0.75 m

- 2 x press molds for chamber packing RI 60 + various insert parts for recesses

- 2 x press molds for rubber panels, riding arena floor panels

- 2 x press molds for rubber panels, box panels

Rubber Press III

Built in 1998 in-house with sliding table, SPS control, feeding system, extensions made of Naxtrasteel ejector.

Specifications:

- Oil-hydraulic under-piston production press, with 5 cylinder under-piston pressing unit.

- Continuous pressing force approx. 3000 tons.

- Upper and lower pressure plate reinforced

- 2 cylinders for rapid feed

- SPS control with switch and control cabinet

The press comes with:

- 2 x molding boxes, 2.00 x 1.00 m

- 2 x press molds for rubber panels, riding arena floor panels, box panels, various press molds for custom panels, floor panels, insulation panels, transmission barriers

Rubber Press IV

Built in 2006, in-house construction.

Specifications:

- Hydraulic press with hinged cover, lockable

- Oil-hydraulic under-piston press, with 14 cylinder under-piston press unit.

- Continuous pressing force approx. 2500 tons.

The press comes with:

- Molding box, 3.00 x 0.75 m

- 2 x molds for chamber packing RI 60

Rubber Press IV

Press for micro-series, custom products.

Specifications:

- Custom-produced by the company

- For the production of pipe saddles, marking panels, ball trays, chamber-filling elements for level crossings

- Oil-hydraulic lower piston production press, with upper piston pressing unit.

- Continuous pressing force approx. 500 tons.

- Manual control

The press comes with:

- Various molding boxes and molds

- The forms of the raw saddles are in the possession of the customer

Presses and machinery for insulation panels

The press cann produce insulation panels from rubber with sheet metal jacket, too.

Rubber Press V

Production press for noise protection and insulation boards. Built in 2002, in-house construction. The press has an SPS control and feeding system.

Specifications:

- Consists of a rotary table,

- Internal diameter 3200 mm, total 8500 mm with 8 molding boxes and lid

- Bottom piston press with 9 cylinders per molding box

- Custom-produced the company

- Molding boxes adjustable from

- 1000 mm x 2000 mm up to

- 1400 mm x 2000 mm

- Height 150 mm

- Lid lockable

- Conveyor system for feeding material to the silo system, length 4500mm (2 pieces)

- Silos with screw conveyor, length 10 m, diameter 3500 mm and 3000 mm (2 pieces)

- SPS control with switch and control cabinet

Sheet metal jacket machinery

The following machinery is used to produce sheet metal jackets for insulation panels from rubber:

Squaring machine

Specifications:

- Custom-produced by the company, operated hydraulically

- Adjustable for processing of metal sheets

- 1000 mm x 2000 mm

- Up to 1400 mm x 2000 mm

CNC machine, rebuilt

Specifications:

- For stamping recesses, Knoevenagel

- Adjustable for sheet sizes

- 1000 mm x 2000 mm

- Up to 1400 mm x 2000 mm

Machinery currently not in use

Press II

The press was built in 1999.

Specifications:

- Oil-hydraulic sub-piston production press, with 5 cylinder sub-piston presses.

- Continuous pressing force approx. 2500 tons.

- Base body made by Sack & Kiesselbach

- Upper and lower pressure plate reinforced

- 2 cylinders for rapid feed.

- Similar to Press I

- Mold box 1700 x 800 mm

- Molds for rubber blocks, e.g. level crossings

- Not ready for use, no switch box or control unit

Test press / small press

The press is an in-house construction. The shape is 30 cm x 30 cm for various material tests and initial trials.

What can you produce with this equipment?

The company’s equipment is designed to produce the following molded goods from rubber:

Equestrian riding arena products, e.g.:

- Piding arena floor panels

- Paddocks

- Enclosures

- Longeing circles

- Horse boxes

- Stable alleys

- Etc.

Flooring panels:

- Outdoor panels

- Boules mats (exhibition flooring

- Rubberized pathways

- Terrace flooring

- Lawn protections mats

- Playground mats

- Lounging mats for animals

- Balcony coverings

- Etc.)

Acoustic insulation panels

- Acoustic barriers

- Sound absorbing rubber mats

- Insulation pnels made from sheet metal

- Etc.

Golf mats

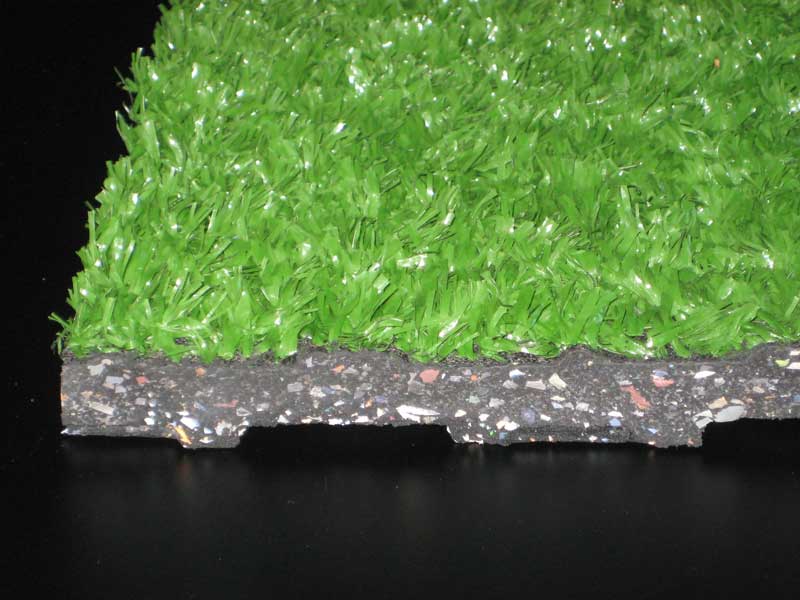

- Artificial turf mats

- Rubber flooring sheets with or without synthetic lawn cover

Chamber-filling elements

- Diverse molded products for industrial and consumer goods sectors

Other molded products from rubber

- A diverse set of molded products for industrial and consumer goods sectors

Sales calculations

The seller provides sales calculation on the basis of production figures for various presses. Write us to inquire for more information about the offer!

Contact Seller

Please fill out form below to get in touch with the owner of the listed equipment. Make sure to submit your phone number to enable the seller get in touch with you directly.