Bridgestone to develop chemical tire recycling technologies for producing isoprene

Bridgestone Corporation – a global tire manufacturer – announced the launch of a joint research and development program with the National Institute of Advanced Industrial Science and Technology (AIST), Tohoku University, ENEOS Corporation and JGC HOLDINGS CORPORATION. This program is aimed at developing chemical recycling technologies that utilize end-of-life tires to achieve high-yield production of isoprene, a raw material for synthetic rubber. By combining the expertise and technologies of industry leading companies and academic institutions, Bridgestone is working to develop innovative recycling technologies that will contribute to the realization of a more sustainable society and to conduct demonstrations for the social implementation of these technologies by 2030.

Tire demand is expected to grow in the future in conjunction with rising automobile and transportation demand. Synthetic rubber is one of the primary materials used when producing tires and is generally manufactured using petroleum today. End-of-life tires are also utilized as fuel mainly through thermal recovery technologies in Japan. At the same time, it is projected that society will come to face issues related to resource depletion and climate change triggered by increased CO2 emissions in the future.

To ensure that it can continue to supply tires in more sustainable manner, Bridgestone has teamed up with AIST, Tohoku University, ENEOS and JGC HOLDINGS to contribute to increased resource recycling and carbon neutrality across the value chains of the tire and rubber industry and the petroleum and petrochemical industry.

The R&D program will promote the social implementation of technologies for high-yield production of isoprene by decomposing used tires with a specialized catalyst. AIST, Tohoku University, and ENEOS will be responsible for the development of chemical recycling technologies of used tires and the related evaluation technologies while JGC HOLDINGS will be tasked with designing pilot plants. As the project leader, Bridgestone will play a central role in the project, guiding demonstrations for social implementation by utilizing its rubber R&D resources and expertise in the tire and rubber industry.

This program on "recycling technologies to achieve high-yield production by decomposing at low temperatures and depolymerization of used tires (brought by Bridgestone)" is one of two research and development (R&D) projects under the initiative called "developing chemical product manufacturing technologies utilizing used tires" promoted by the New Energy and Industrial Technology Development Organization (NEDO) of Japan and adopted as part of "the Green Innovation Fund" of NEDO.

The Ministry of Economy, Trade and Industry (METI) of Japan decided to develop the Green Innovation Fund toward the goal of achieving carbon neutrality by 2050, the sustainability goal of Japanese government. The fund continuously supports companies and other organizations which address challenges to achieve the goal as part of their business from R&D to demonstrations to social implementation of the outcomes for the coming ten years.

Through this program, AIST, Tohoku University, ENEOS, JGC HOLDINGS, and Bridgestone seek to help increase synthetic rubber recycling and achieve carbon neutrality in the tire and rubber and the petroleum and petrochemical industries and to contribute to the realization of a more sustainable society.

To read the full article, please proceed to Bridgestone’s website.

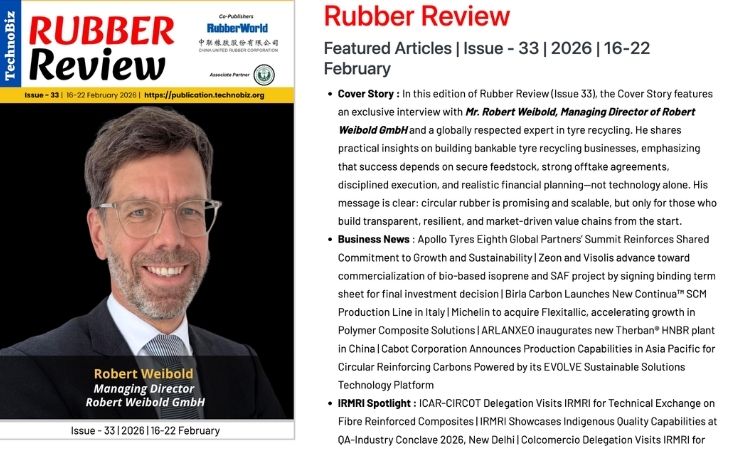

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.