Tire Recycling Consulting

Pyrolysis Consulting

Shop

Webinars

Used Equipment

Advertising

News Events FAQ About Us Contact Search

News Events FAQ About Us Contact Search

Tire Recycling

If you are contemplating a new tire recycling plant, Weibold can conduct an in-depth study of the markets and technologies for a given budget. The Pre-Feasibility Study helps project initiators, investors or lenders make informed decisions. It defines and optimizes a concept for a specific location and situation. The Study also will serve as a blue-print for further project development.

Switch to tire pyrolysis

Conceiving an economically viable tire recycling plant is an iterative process that has to investigate, eliminate and make trade-offs on a large number of variables. This requires a methodical approach.

Each tire recycling business is different. Feedstock, markets, CAPEX limits, and technology choices are interdependent and any one parameter can have a large impact on the final economy and profitability of your operation.

The Pre-Feasibility Study helps you zero in on a concept that is adapted to your particular situation. It serves as a blue-print for further economic, market and technical development of the project as it moves from concept to execution.

The pre-feasibility study will allow you to make informed decisions on funding to be secured, markets to be explored, products to be developed, and the technology to be acquired or licensed. It also provides a road-map for the phased development of prime customers and corresponding products in your tire recycling business. During fund raising efforts you will also be able to use the study as referenceable third party document for partners, parent companies, investors, and lenders.

Economic viability of a tire recycling plant depends on the intelligent productization of the materials produced. Weibold’s approach to conceiving a successful project is to clearly define the markets before choosing the products, technology, or associated processes. We recommend – in a first phase - establishing a baseline cashflow from a simple product line, and – in a second phase – add process steps to increase the value added of the products sold. Recommendations for products will be given based on an array of successful examples in the global tire recycling industry. Our objective is to strive towards a high material recovery component, away from tire incineration markets. This concept is implemented in the analysis of the study and helps move the industries towards a circular economy while protecting the investments from phase to phase.

Weibold is conducting trend, market and technology studies for Clients around the globe. Our Clients include plant operators, investors, lenders, recycling associations, technology providers, and product manufacturers. Now selected cross sections of the knowledge we have collected and pooled in our research database is available for recycling strategists and operators looking for innovations and trends on specific subjects in world-wide markets.

The full-scale Bankable Business Plan gives the Client a detailed industry description and outlook, inform about existing and future target markets, include a competitor analysis, financial modelling tool as well as information about regulations. Recycling tires into materials such as steel-free crumb rubber and fine rubber powder used to be a profitable venture; however, due to market saturation in developed economies, tire recycling companies might want to shift their focus from raw materials to potentially higher-priced consumer goods made from recycled rubber or even virgin rubber which can be replaced by tire-derived materials.

In this Pre-Feasibility Study, Weibold considers the latest developments world-wide in utilizing ELT derived textile fraction for purposes other than incineration. The work will result into a list of companies, explaining the following: a) the methods for processing, b) the technical readiness level, c) any successful references, d) logistical considerations (low weight/volume vs. capital investment), e) and to what extent this application could be applied to the Client's specific situation.

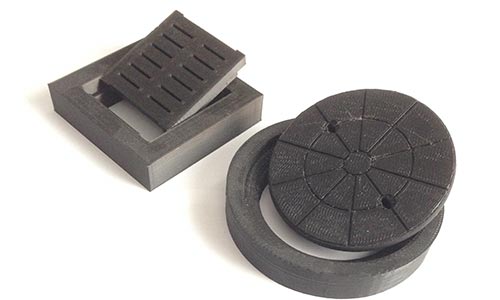

The document is both an introduction to manufacturing of sewer covers and grids made out of end-of life tires (ELT) explaining input materials, processing techniques, manufacturers, suppliers of technology, prices, materials, characteristics, life expectancy, etc. It will be based on research and preparatory work performed for the specific situation of the customer in the target area. Recycling tires into materials such as steel-free crumb rubber and fine rubber powder used to be a profitable venture; however, due to market saturation in developed economies, tire recycling companies might want to shift their focus from raw materials to potentially higher-priced consumer goods made from recycled rubber or even virgin rubber which can be replaced by tire-derived materials.