Tire Recycling Consulting

Pyrolysis Consulting

Shop

Webinars

Used Equipment

Advertising

News Events FAQ About Us Contact Search

News Events FAQ About Us Contact Search

Tire Recycling

Get recommendations for process improvements and/or equipment modifications to create higher value rubber products, improve margins, increase throughput of your tire recycling business, or operate under better HSE standards.

Switch to tire pyrolysis

Operators of existing tire recycling plants constantly strive to improve their process and their products. Weibold’s Plant Improvement consulting services will assess your existing installations and product results and provide you with options and recommendations for modifications or additions to the equipment and processes currently in use.

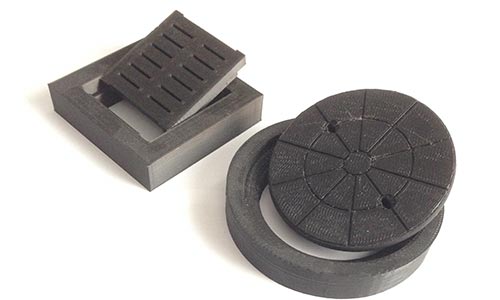

Next to pure tire processing improvements Weibold also can provide guidance on implementation of proven innovative manufacturing processes using moulds and TPEs to produce high value products.

Depending on the objective(s) chosen at the start of the service, you will be able to derive one more of the following benefits:

Weibold will first perform a detailed analysis of the tire recycling equipment and processes currently in use. We will then draw on experiences gained from operators world-wide and a large database of suppliers to list options for solutions for the stated objectives. Both technical and economic factors will be considered. A final report will be issued listing and ranking available options and a recommending a course of action to upgrade your tire recycling business.

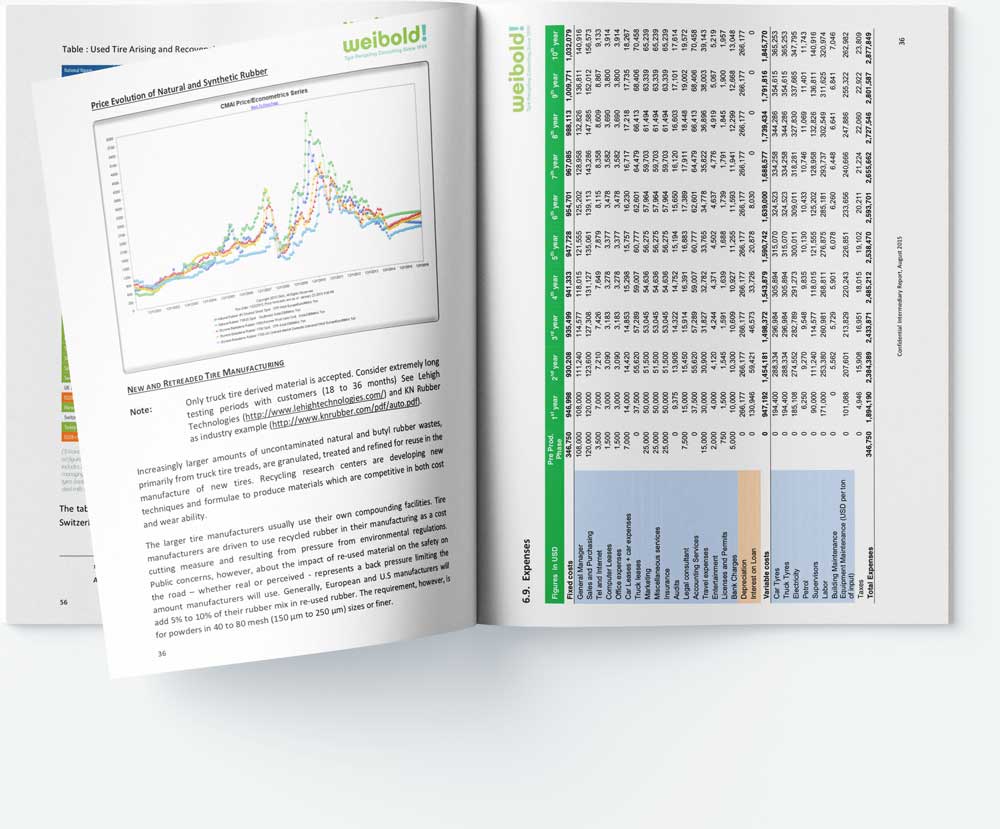

Weibold is conducting trend, market and technology studies for Clients around the globe. Our Clients include plant operators, investors, lenders, recycling associations, technology providers, and product manufacturers. Now selected cross sections of the knowledge we have collected and pooled in our research database is available for recycling strategists and operators looking for innovations and trends on specific subjects in world-wide markets.

The full-scale Bankable Business Plan gives the Client a detailed industry description and outlook, inform about existing and future target markets, include a competitor analysis, financial modelling tool as well as information about regulations. Recycling tires into materials such as steel-free crumb rubber and fine rubber powder used to be a profitable venture; however, due to market saturation in developed economies, tire recycling companies might want to shift their focus from raw materials to potentially higher-priced consumer goods made from recycled rubber or even virgin rubber which can be replaced by tire-derived materials.

In this Pre-Feasibility Study, Weibold considers the latest developments world-wide in utilizing ELT derived textile fraction for purposes other than incineration. The work will result into a list of companies, explaining the following: a) the methods for processing, b) the technical readiness level, c) any successful references, d) logistical considerations (low weight/volume vs. capital investment), e) and to what extent this application could be applied to the Client's specific situation.

The document is both an introduction to manufacturing of sewer covers and grids made out of end-of life tires (ELT) explaining input materials, processing techniques, manufacturers, suppliers of technology, prices, materials, characteristics, life expectancy, etc. It will be based on research and preparatory work performed for the specific situation of the customer in the target area. Recycling tires into materials such as steel-free crumb rubber and fine rubber powder used to be a profitable venture; however, due to market saturation in developed economies, tire recycling companies might want to shift their focus from raw materials to potentially higher-priced consumer goods made from recycled rubber or even virgin rubber which can be replaced by tire-derived materials.