Weibold Academy: Chemical recycling – environmental impacts of end-of-life tire pyrolysis

Weibold Academy article series discusses periodically the practical developments and scientific research findings in the end-of-life tire (ELT) recycling and pyrolysis industry.

This article is a review by Claus Lamer – the senior pyrolysis consultant at Weibold. One of the goals of this review is to give entrepreneurs in this industry, project initiators, investors and the public, a better insight into a rapidly growing circular economy. At the same time, this article series should also be a stimulus for discussion.

For the sake of completeness, we would like to emphasize that these articles are no legal advice from Weibold or the author. For legally binding statements, please refer to the responsible authorities and / or specialist lawyers.

Introduction

The International Organization for Standardization (2008, 2013) defines chemical recycling as a production of new raw materials by changing the chemical structure of polymers (e.g., plastic, rubber) through depolymerization, excluding energy recovery and incineration. Whereby depolymerisation is understood as a reversion of a polymer to its monomer(s) or to a polymer of lower relative molecular mass. This irreversible chemical decomposition (depolymerization) in pyrolysis processes is caused solely by a rise in temperature in an inert or oxygen free environment (UIPAC, 2021).

The chemical recycling of end-of-life tires (ELT) through pyrolysis is therefore a recycling operation by which waste materials (ELTs) are reprocessed into chemical products (recovered Carbon Black and tire-derived-oil (TDO)) to become input feedstock for chemical plants. The chemical recycling of end-of-life tires (ELT) via state-of-the-art pyrolysis technologies does not only avoid greenhouse gas emissions compared to today’s conventional production processes, but it also increases the resource efficiency while closing the loop in the transition to a circular economy.

However, civil organisations criticise the production of fuel through chemical recycling. Sometimes they mutilate the terminology, pointing to the associated environmental impacts, while they overlook the fact that modern ELT pyrolysis concepts are not geared towards the production of "fuels" (which, by the way, should not be defined as "recycling" but rather as less preferred "recovery" according to the EU waste hierarchy), but rather towards generation of new (secondary) raw materials.

Critics of chemical recycling also like to point out that energy must be supplied for the pyrolysis process (which is naturally also associated with some GHG emissions) and/or that the product output (e.g., recovered carbon black) must be processed further (milling, pelletizing) to be saleable to the industry.

At this point, we shall refrain from raising a finger by schoolmasterly pointing out that no industrial production process (of whatever type) is known that does not require energy input and multi-stage production steps. The question rather must be what the overall balance of the chemical recycling of ELTs is for the environment and resources (not forgetting the economics): It was already possible to show many years ago in a much-cited comprehensive life cycle assessment (Li et al., 2010) that pyrolysis of ELTs is the best recycling technology among all known mechanical and non-mechanical ELT recycling technologies. [1]

It should be noted that the academic literature published to date on ELT pyrolysis LCAs all refer to technologies that are absolutely outdated (e.g., batch cycle lasting 11 hours, etc.) and were using coal-generated electricity.

Modern pyrolysis technologies, on the other hand, are equipped with efficient exhaust gas and /or flue cleaning facilities, use an electricity mix from renewable energy sources, recycle excess energy for the process (reduced energy consumption), and have state-of-the-art control and safety systems (etc.). This leads to an even better overall environmental profile, in which the predominantly positive effect on human, environment, and resources is again greatly increased compared to the status-quo in 2010.

The most eco-effective ELT recycling technology

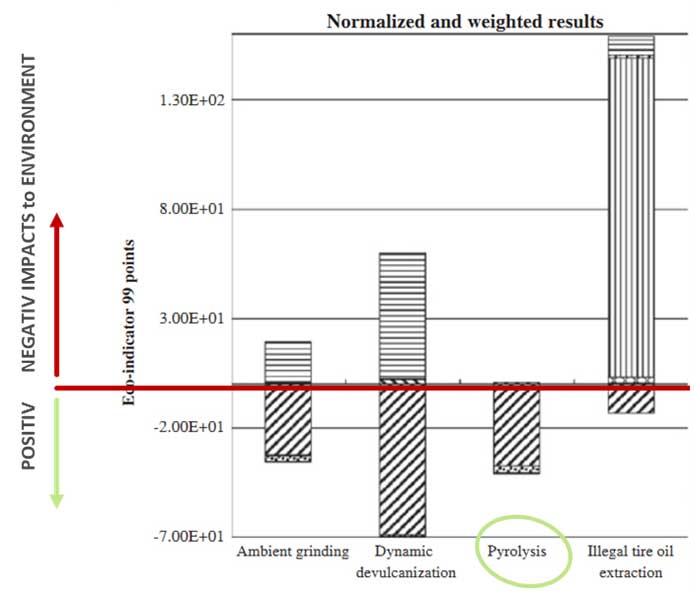

The aim of a “Chinese case study” by Xingfu Li and colleagues published in 2010 [ref. 1] was to compare different end-of-life tire (ELT) treatment technologies in China from an environmental and economic perspective. Three legal treatment technologies were evaluated: ambient grinding, devulcanization, and pyrolysis (additionally also the illegal tire oil extraction).

A Life cycle assessment (LCA) was applied to evaluate the potential environmental impact of each treatment based on the Eco-indicator 99 (Hierarchist approach) method provided by GaBi 4 software. The result shows that pyrolysis represents the environmentally benign option (while illegal tire oil extraction logically caused the worst damages).

Li further suggested avoiding impact as to respiratory effects (inorganic) dominantly contributed by the energy production stage (remark: coal remains the largest contributor to China's energy mix), that the emphasis should shift from the control of emissions (which nonetheless remains important) to the reduction of energy consumption for all three legal ELT treatment methods.

A simplified comparison of net benefits and total impacts in this much-cited comprehensive study shows that the most eco-effective ELT treatment technology is pyrolysis, followed by dynamic devulcanization and ambient grinding.

Figure: Li et al.; Comparison of the total impacts for the four ELT treatment technologies. | Graphics by ((c) Elsevier Ltd., 2010).

Pyrolysis as an environmentally effective solution

A more recent study by Müfide Banar (published in 2015) [ref. 2] researched the environmental impact of a waste tire pyrolysis plant in Turkey using the Life Cycle Assessment (LCA) method. As mandated by ISO 14040 guiding the methodology of an LCA, the system boundary, including feedstock pre-treatment and pyrolysis, was defined, and material/energy flows, including raw material, pyrolysis products were determined according to a pilot pyrolysis plant (batch cycle lasting 11 hours) and literature data. The LCA calculations were carried out using SimaPro 8 software.

At the impact assessment step, the CML-IA baseline (V3.00) method was applied for selected impact categories (abiotic depletion, global warming, human toxicity, marine aquatic toxicity, acidification, and eutrophication).

The characterization results show that all the impact categories have negative values (which means avoided impacts to the environment), except for acidification. Negative values resulting from avoided products were due to the valuable products of pyrolysis (rCB and TDO). The acidification impact resulted mainly from SO2 emissions in combustion flue gases. In summary the results show that utilization of pyrolysis products in sufficient quantities and the application of flue gas treatment systems (note: which is already standard today) play an important role in presenting pyrolysis as an environmentally effective solution for waste tires.

Banar shows that the substitution of primary resources (e.g., crude oil and ores) with ELT derived pyrolysis products (recovered carbon black and pyrolysis oil) enables exorbitant environmental savings.

The following savings are worth mentioning:

- Resource savings in steel alloys, crude oil, and coal

- Reduced greenhouse gas emissions (CO2 is the most important avoided emission)

- Reduced human toxicity through avoided chromium VI production in steel production

- Avoided aquatic toxicity in steel production (especially beryllium, cobalt, hydrogen fluoride, nickel, and vanadium)

- Avoided acidification potential (SO2; sulfur dioxide)

- Avoided eutrophication effects by substituting petroleum-based products and carbon black production (avoided environmental effects are NOx and phosphate emissions, etc.)

Huge contribution to climate change mitigation

Nowadays it is undisputed that the chemical recycling of end-of-life tires (ELT) through pyrolysis make an important contribution to climate change mitigation.

Industrially produced blends of commercial Carbon Black (CB) with the environmentally friendly and sustainable recovered Carbon Black (rCB), have not only proven their technical and commercial maturity, but also contribute to a significant improvement in the ecological footprint of the Carbon Black.

- One of the world's largest virgin Carbon Black manufacturers (Birla Carbon) publicly confirmed in its current Sustainability Report (2021) that recovered Carbon Black (rCB), obtained through chemical recycling (pyrolysis) of end-of-life tires through Circtec’s process, eliminates 3.1 tons of direct and indirect CO2 emissions (per ton of ContinuaTM rCB) when compared to conventional manufacturing of carbon black (per ton of virgin CB).

- Already in 2017 Black Bear Carbon (BBC) published (RubberWorld, Feb. 2017) excerpts from an LCA provided by Partners of Innovation which indicates tremendous positive environmental impact by using ELTs in the BBC process as an alternative to using fossil feedstock in the conventional furnace process. In addition to saving 2,000 to 2,500 litres of crude oil per ton of furnace carbon black (and up to 10,000 litres for speciality grades), it also reduces air pollution, has a very attractive carbon footprint, and produces net green energy. This results in a net CO2 reduction of 4.8 tons of CO2 per ton of recovered carbon black (rCB) produced compared to conventional carbon black production. (RubberWorld, Feb. 2017)

- In 2019 Scandinavian Enviro Systems AB (Enviro) demonstrated the environmental benefits of recovered carbon black according to a LCA from the IVL Swedish Environmental Research Institute. Recovered carbon black leads to CO2eq emissions that are 79-84% lower than the emissions from the production of virgin carbon black. The purpose of this analysis was to provide an overall picture of the materials' environmental impact, and the results show that for each ton of recovered carbon black that replaces virgin carbon black, total emissions are reduced by 1.43-2.00 tons of CO2eq.

- Bolder Industries (Bolder) recently presented their life-cycle analysis (LCA) which was technically evaluated by ThinkStep. The environmental savings based on Bolder technology was stated as 7.5 tons of CO2eq. per ton of rCB produced compared with conventional CB production. Further savings are significant amounts of water and electricity.

- Most recently Pyrum Innovations AG (Pyrum Innovations) had the CO2 savings of their pyrolysis process determined as part of a "Life Cycle Assessment" (LCA, eco-balance) by the prestigious Fraunhofer Institute for Environmental, Safety and Energy Technology. The results prove the sustainable efficiency of the Pyrum technology. Compared to the use of fossil raw materials, the Pyrum pyrolysis process saves 965 kg of CO2eq. per ton of end-of-life tires (ELTs). This would equate to approximately 3.0 tons of CO2eq per ton of rCB saved compared with conventional CB production. When compared to the current recycling mix for ELTs in Germany, Pyrum performs up to 72% better (52% material recycling, 42% incineration in cement plants and 6% in power plants).

- The heavy fraction of the tire-derived pyrolysis oil (TDO) – supplied by German-based Pyrum Innovations - can serve as a substitute for the Carbon Black feedstock (CBFS) in the furnace process (see the EU-funded “BlackCyle” project under the coordination of the tire manufacturer Michelin and a leading carbon black producer Orion Engineered Carbons), thereby reducing the considerable emissions during the extraction and refining of crude oil.

- BASF (Ludwigshafen) recently presented a specific ChemCyclingTM life-cycle assessment (LCA) for various sustainable chemical products produced. Within these studies BASF compared the CO2 emissions between their BASF Ultramid® B base polymer (PA6) production from ELT pyrolysis oil (supplied by New Energy Kft., Pyrum Innovations AG, and ReOil SP. Z O.O.) and naphtha. The result shows that 1-ton of PA6 produced from tire-derived pyrolysis oil (TDO) under a mass balance approach, emits 1.3 ton less CO2 than 1-ton PA6 produced from fossil feedstock (naphtha).

Conclusion

Chemical recyclers that process end-of-life tires using pyrolysis are manufacturers of environmentally sustainable chemical feedstocks (rCB and TDO) for the chemical and rubber industry. State-of-the-art pyrolysis technologies do not only avoid greenhouse gas emissions compared to today’s conventional production processes, but also increases the resource efficiency while closing the loop in the transition to a circular economy.

A much-cited comprehensive LCA study published in 2010 has already shown that the most eco-effective ELT treatment technology is pyrolysis, followed by dynamic devulcanization and ambient grinding. A more recent LCA study published in 2015 shows that the substitution of primary resources with ELT derived pyrolysis products (recovered carbon black and pyrolysis oil) enables exorbitant environmental savings.

These older studies took place at times when technology was "generations behind the state of the art in today's ELT pyrolysis technology", yet (nevertheless) produced a clearly positive result for chemical recycling of ELTs. Modern pyrolysis technologies, on the other hand, are equipped with efficient exhaust gas and /or flue cleaning facilities, use an electricity mix from renewable energy sources, recycle excess energy for the process (reduced energy consumption), and have state-of-the-art control and safety systems (etc.). This leads to an even better overall environmental profile, in which the predominantly positive effect on humanity, environment, and resources is again greatly increased compared to 2010 or 2015.

Recent LCA indicates tremendous positive environmental impact and significant savings in resources, CO2 emissions, water, and electricity use. Although these analytic results by a wide range of suppliers vary, one can safely assume that the chemical recycling of ELTs through pyrolysis eliminates between 3 and 4 tons of direct and indirect CO2 emissions compared to today’s conventional production processes.

Nowadays, all leading ELT pyrolysis companies are also repeatedly tested and certified by sustainability schemes (ISCC, ECOLOOP, EPEA cradle-to-cradle, TÜV, etc.).

In summary we can categorically conclude that, since operations of state-of-the-art chemical tire recycling (pyrolysis) plants are producing sustainable chemical feedstocks, they thereby support the overarching and concrete specified goals of the EU Green New Deal as well as the UN Sustainable Development Goals and significantly contribute to the GHG reductions in the manufacture of carbon black and base chemicals.

References

- Xingfu Li, He Xu, Yingnan Gao, Yijun Tao, Comparison of end-of-life tire treatment technologies: A Chinese case study, Waste Management, Volume 30, Issue 11, 2010, Pages 2235-2246, ISSN 0956-053X, https://doi.org/10.1016/j.wasman.2010.06.006.

- Banar, Müfide. (2015). Life cycle assessment of waste tire pyrolysis. Fresenius Environmental Bulletin. 24.1215-1226.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.