Continental and Pyrum sign 10-year agreement for recovered carbon black

On July 30, 2024, Pyrum Innovations AG (Pyrum) and Continental signed a framework agreement for the long-term purchase of Pyrum’s recovered Carbon Black (rCB). The agreement covers the rCB purchase quantities for at least two Pyrum plants, with a term of ten years. Continental will also supply Pyrum with end-of-life tires. In addition, Continental has agreed to make an advance payment for future rCB deliveries.

The two companies are thus intensifying their cooperation. Continental had already signed a development agreement with Pyrum Innovations in 2022. Since then both companies share the common goal to further optimize and expand the recycling of end-of-life tires through pyrolysis.

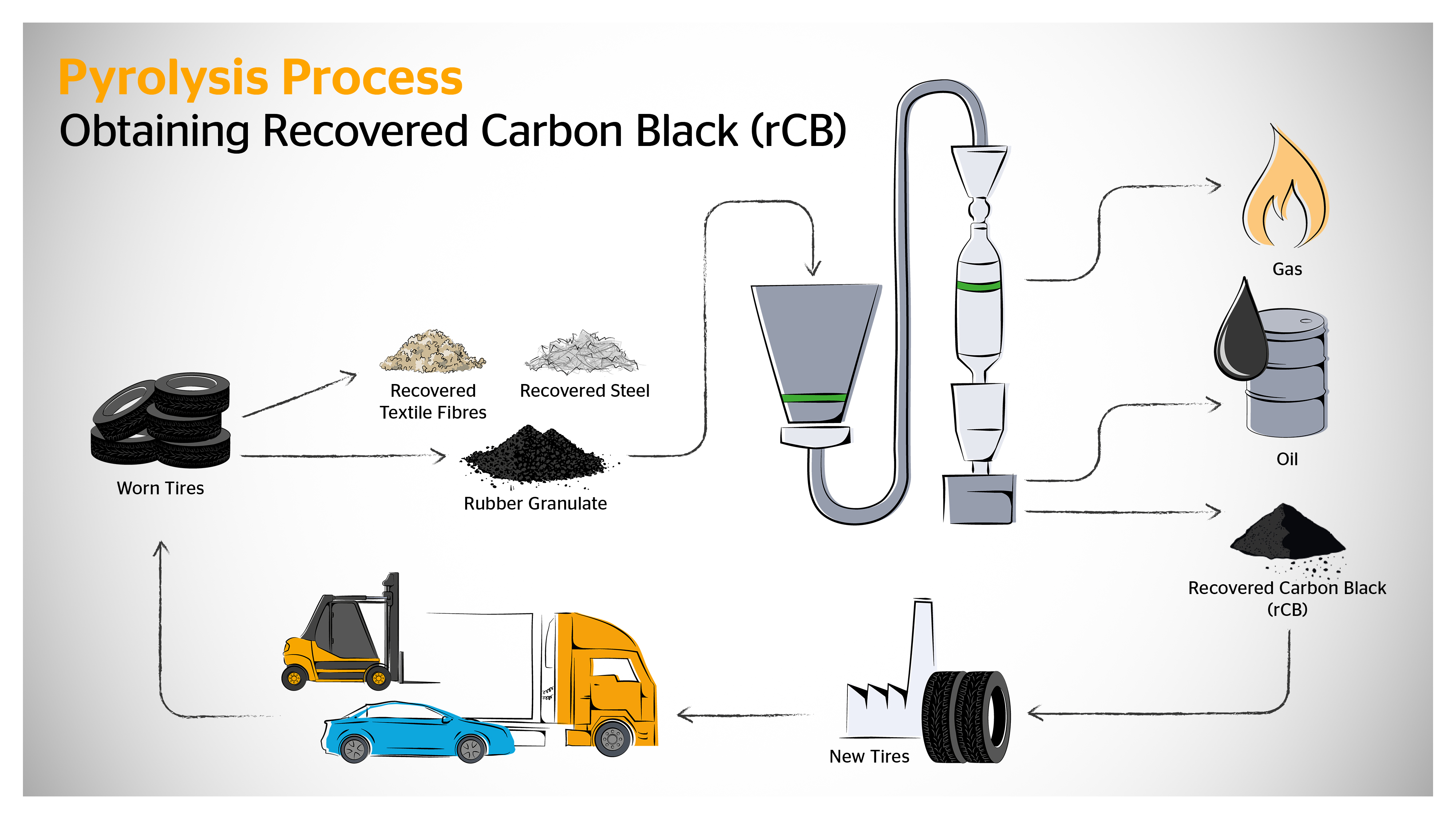

Recycling management concept for the recycling of end-of-life tires, including the extraction of recovered carbon black (rCB). | Image by Continental.

Carbon black is an important raw material both for tire production and for the manufacture of other industrial rubber products. The use of carbon black in rubber compounds increases the stability, strength and durability of tires. Carbon black recovered from end-of-life tires helps reduce the use of fossil raw materials and CO2 emissions. In a passenger car tire from Continental, the soot content, giving the tire its black color, is between 15 and 20 percent, depending on the model. By using recycled carbon black, Continental is one step closer to its goal of using more than 40 percent renewable and recycled materials in its tires by 2030.

Pascal Klein, CEO of Pyrum Innovations AG: “The expansion of our collaboration with Continental is a very important step for us. To enable Continental to use our rCB in the series production of car tyres in the future, we are continuously working on its further development as part of a development partnership. Together, we have already succeeded in ensuring that all newly produced forklift tyres at the Continental tyre plant in Korbach, Hesse, contain our rCB.”

Jorge Almeida, Head of Sustainability at Continental’s tire division: “Recycled raw materials are becoming increasingly important in our tire production. For us, the end of a tire’s service life is just the end of its current use phase. Our aim is to continue to use products, components and materials sensibly after the first utilisation phase. We can only increase the recyclability of our products if we rethink. The end of a tire’s service life must become the beginning of a new opportunity. Together with Pyrum, we are developing highly efficient processes to return as many components and materials as possible from a used tire back into our production cycle.”

The new Pyrum plant is to be built in Perl-Besch on the Moselle by the end of 2025 and will double Pyrum’s recycling capacity from 20,000 tonnes to 40,000 tonnes of end-of-life tires. The final application documents for the early start of construction are currently being prepared and are expected to be finalised and submitted by the beginning of August 2024. Once the application documents have been approved, the ground-breaking ceremony will take place at the new site in Perl-Besch. Construction is currently scheduled to start at the beginning of October 2024.

Press release by Pyrum.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.