Maris presents its efficient rubber devulcanization technology for end-of-life tires

Since it was founded in 1962, Maris, an Italian manufacturer of co-rotating twin-screw extruders, has claimed one of the leading positions in the research of new state-of-the-art applications for its products.

With the aim of providing its customers with the widest range of choices, every mechanical component of Maris’ extruders are entirely in-house manufactured. Maris says it’s one of the few companies in the world able to customize its co-rotating twin-screw extruders according to its customers’ specific needs and this is true also when it comes to rubber devulcanization.

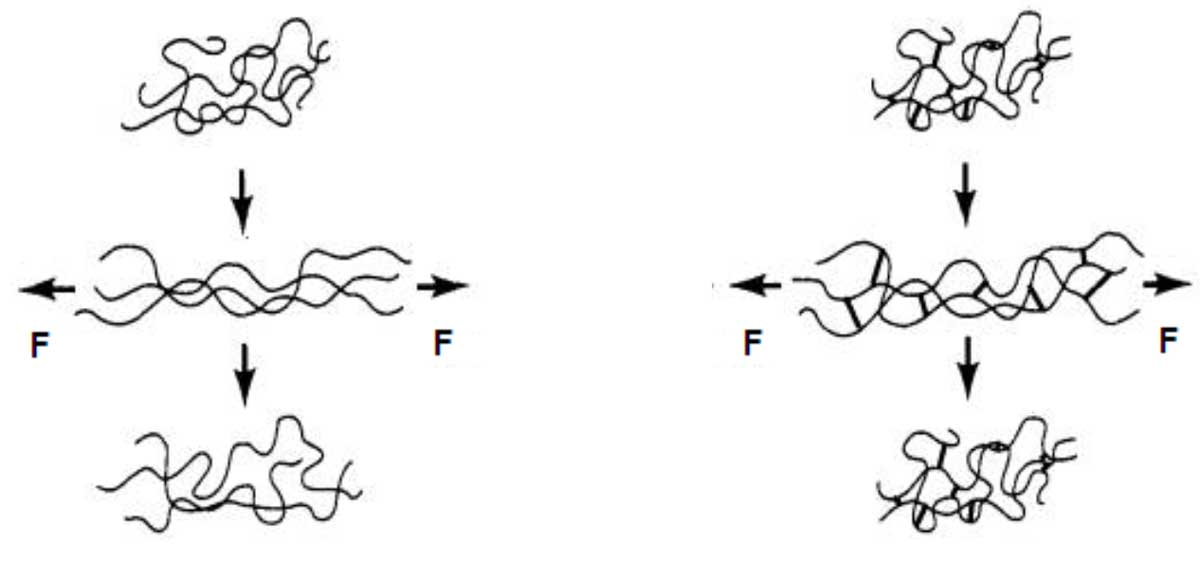

Rubber devulcanization is a selective breaking process of an elastomer S-S and C-S bonds, which produces only a limited degradation of the polymeric structure (C-C bond).

Nowadays, different methods to obtain a devulcanized product are known and may be physical (ultrasound, microwaves, and mechanical stress), chemical (the use of devulcanization additives) and synergistic (thermo-mechanical, thermo-chemical).

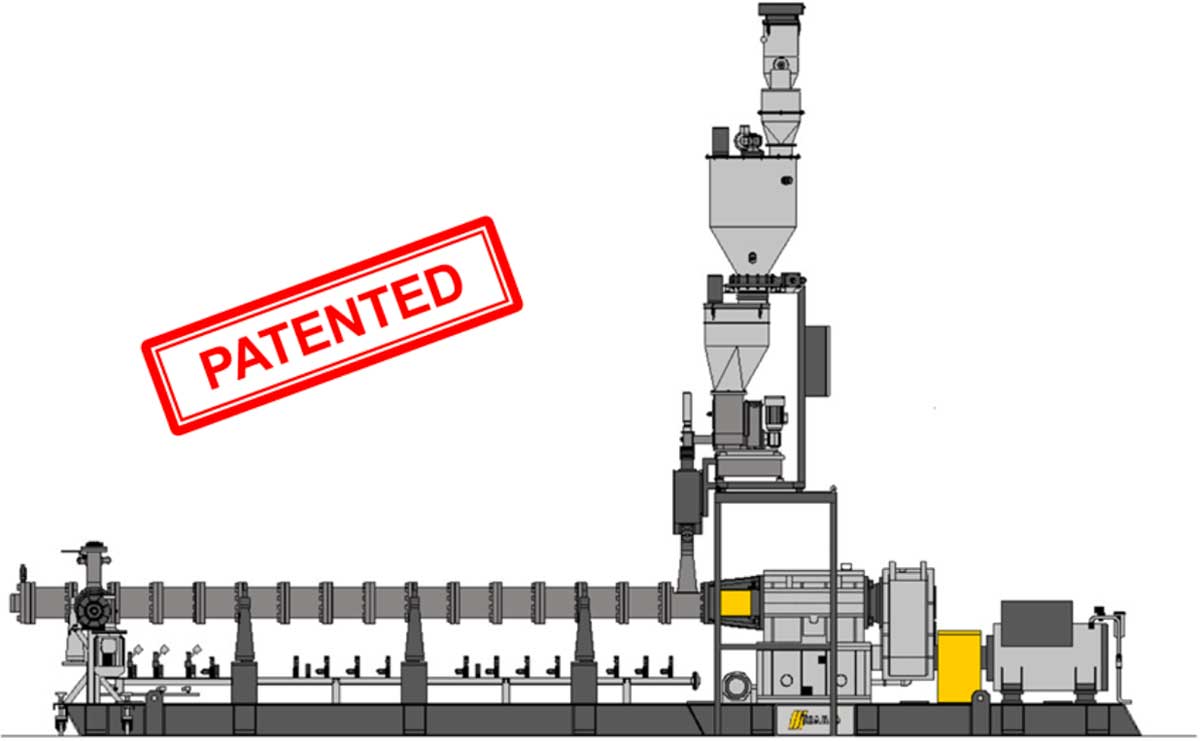

Maris, who is active in the rubber devulcanization and extrusion field for more than 10 years now, has developed a patented thermo-mechanical synergic process – without the use of chemical additives – that has been used on a large industrial scale and which involves the rubber transition from an elastomeric cross-linked system (vulcanized rubber) to a plastic non-cross-linked system (devulcanized rubber).

Left: plastomer, entanglement (physical interaction). Right: elastomer, crosslinking (chemical bond). | Image by Maris Corp..

The thermo-mechanical devulcanization is possible as S-S, C-S and C-C bonds have different characteristics; a significant difference in terms of elastic bonding constant (kcc≈100> kcs> Kss≈3) and a different bonding energy (respectively 270, 310, 370 kJ / mol). Thanks to the appropriate combination of and mechanical thermal energy, it is possible to selectively break the S-S and C-S bonds.

Rubber extrusion and devulcanization equipment by Maris, Italy. | Photos by Maris Corp.

Maris devulcanization process allows working with the following types of rubbers:

- ELTs – End-of-Life Tires

- Car tires

- Truck tires

- Off road tires

- ACM - Polyacrilic Rubber

- BR – Butadiene Rubber

- EPDM - Ethylene Propylene Diene Monomer

- FKM - Fluorelastomers

- IIR - Butyl Rubber

- IR - Isoprenic Rubber

- NR - Natural Rubber

- Q - Siliconic Rubber

- SBR - Styrene Butadiene Rubber

Chemical and rheological analysis carried out on devulcanized material, have shown that – through this process – a devulcanization yield of 60-80% can be obtained.

Furthermore, it is possible to re-use – in general - from 15 to 50% of the devulcanized material for the same application of origin and, according to the material final use, it is possible to increase the percentage of devulcanized material of the final compound (over 50%).

In terms of mechanical properties of the final compound, Table 1 compares the mechanical properties of an IR-based vulcanized compound (100% virgin) and a vulcanized compound containing 40% of devulcanized IR, both used for the same application and vulcanized in the same way.

| Parameters | IR: Virgin | IR: Devulc.(40%) + Virgin(60%) |

|---|---|---|

| Modulus at 100% (M Pa) | 0.95 | 0.90 |

| Modulus at 300% (M Pa) | 1.78 | 1.75 |

| Tensile strength (M Pa) | 22.91 | 19.94 |

| Elongation at break (%) | 891 | 835 |

| IRHD Hardness | 67.1 | 62.2 |

| Elastic Yield | 48.4 | 42.8 |

Comparison of mechanical properties of an IR-based vulcanized compound (100% virgin) and a vulcanized compound containing 40% of devulcanized IR, both used for the same application and vulcanized in the same way. | Data by Maris Corp.

The table shows that potential losses of the devulcanized virgin system – in terms of mechanical properties – are negligible and comparable to the non-devulcanized virginproduct by further confirming the effectiveness of this thermo-mechanical process within the field of rubber devulcanization.

Devulcanization therefore allows an effective use of vulcanized rubber waste and the possibility to obtain a second raw material by reducing the costs and the consumption of virgin material.

Layout of an extruder for devulcanization. | Graphics by Maris Corp.

| C-TSE size (mm) | 20 | 30 | 40 | 50 | 58 | 70 | 80 | 92 | 112 | 133 |

|---|---|---|---|---|---|---|---|---|---|---|

| Output (kg/h) | 5 10 | 20 30 | 50 80 | 80 100 | 100 150 | 150 250 | 150 350 | 400 500 | 550 650 | 700 800 |

At Maris Technological Center, it is possible to carry out devulcanization tests in order to verify the effectiveness of the process.

Video by Maris Corp.

To learn more about the end-of-life tire rubber devulcanization technology by Maris, please visit the company’s official website.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.