OTR tire devulcanization project receives support in Australia

International Mining (IM) magazine reports that MMG’s Dugald River underground zinc mine Cloncurry in Queensland, Australia is tackling how to recycle end-of-life tires. According to the magazine, the mine annually generates about 920 end-f-life tires from technical vehicles and trucks.

The Council of Australian Governments decided to ban used and end-of-life tire exports from December 2021, and the country is now facing a growing tire stockpile problem.

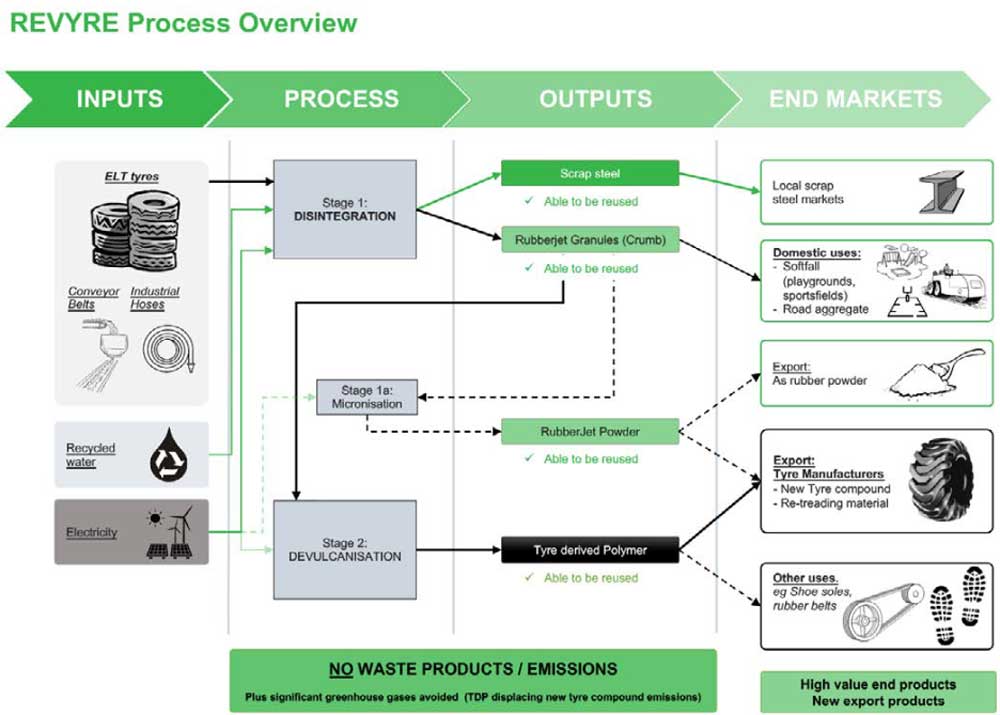

According to IM, Dugald River and its mining contractor Barminco have investigated alternative tire disposal, supporting a joint venture – REVYRE – program with Energy Estate and InfraCo. Reportedly, a proposed recycling process breaks down and repurposes end-of-life tires into a high value polymer product fit for tire manufacturing and clean high tensile scrap steel.

REVYRE is a low emission rubber polymer recovery and re-processing business for end-of-life rubber products including end-of-life tires, conveyor belts and like products. It utilizes award winning, recently commercialized technologies in its two-step recycling process and is the only available genuine industry solution for the re-use of rubber in the circular economy.

REVYRE OTR tire devulcanization process overview. | Photo by REVYRE & IM.

The company’s recycling process “is chemical and solvent free with near zero waste and emissions or by-products making it an environmentally friendly technology.” REVYRE is also looking at renewable energy for its operations. This aligns with its low carbon footprint aspiration while reducing the environmental impact of tire production. Barminco and MMG say they are proud to support this responsible initiative. A number of REVYRE plants are planned for each Australian mainland state supporting new jobs made possible from the development, construction and operation of the sites. The new plants have the potential to further reduce the carbon footprint burden that came with end-of-life tires being previously recycled in Victoria.

REVYRE newsletter highlighting the compan's progress. | Source: REVYRE.

One of the new REVYRE press releases says the group has made considerable progress in the last six months in regards to its facility in the Mount Isa region of Queensland. According to IM, there is an agreement in place with Economic Development Queensland to acquire to acquire the first Australian site. The site is located within the Nordale Industrial Precinct. REVYRE has received a number of Letters of Intent from major mining companies in the region who have agreed to supply feedstock to the plant once it is operational. The vision for the Mount Isa site, as a flagship for REVYRE in Australia, is that it will deliver on emissions- free solutions for the users of OTR tires regionally and create reskilling opportunities, training opportunities and new enduring jobs.

The magazine also reports that REVYRE has also been selected as a project for inclusion in Beyond Zero Emissions’ Renewable Energy Industrial Precincts (REIPs) proposal for the Hunter and Gladstone regions. The REIPs are designed to support domestic manufacturing opportunities and drive regional economic development through sustainable and renewably powered technologies. The REVYRE plant in the Upper Hunter region will be located within an industrial estate to be developed on the land currently occupied by one of the first coal mines in Australia. This site is owned by Idemitsu Australia Resources (IAR), the large Japanese resources company and the coal mine is scheduled for closure in 2022. The industrial precinct forms part of their redevelopment plans which will transform the existing mine into the Muswellbrook Energy, Training and Industrial Precinct.

To learn more about the story, we encourage you to read original article at International Mining and visit REVYRE.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.