Weibold Academy: ASTM Committee D36 Advances Standards for rCB

Weibold Academy article series periodically discusses practical developments and scientific research findings in the end-of-life tire (ELT) recycling and pyrolysis industry.

The current article is a review by Yogesh Gaikwad – the technical consultant for carbon black at Weibold. One of the goals is to give entrepreneurs in this industry, project initiators, investors, and the public, a better insight into a rapidly growing circular economy. At the same time, this article series should also be a stimulus for discussion.

For completeness, we would like to emphasize that these articles are no legal advice from Weibold or the author. Please refer to the responsible authorities or specialist lawyers for legally binding statements.

Introduction

ASTM International, formerly the American Society for Testing and Materials, is a globally recognized leader in developing and delivering voluntary consensus standards. Founded in 1898, ASTM provides a forum for producers, users, consumers, and other stakeholders to create and update standards transparently. The organization supports industries worldwide by offering over 12,000 standards that enhance safety, quality, and performance across various sectors. ASTM standards are utilized in research, product development, and quality assurance to improve public health and safety.

The ASTM Committee D36 on Recovered Carbon Black (rCB) chaired by Pieter Ter Haar was established in 2017 to develop standards for rCB and its related processes. The primary focus is on addressing the quality and safety needs of the rCB industry through the development of voluntary consensus standards.

The committee's activities are organized into four technical subcommittees which create and maintain test methods, practices, terminology, and guide standards. These subcommittees work collaboratively to develop comprehensive standards for the rCB industry.

The Committee D36 meets biannually, holding one-day technical meetings in June and December. Approximately 40 members attend these meetings. The committee boasts a total membership of 106 individuals. The standards developed by D36 are published in the Annual Book of ASTM Standards.

The scope of Committee D36 includes promoting knowledge about the properties of rCB, stimulating research, and developing various test methods, specifications, classifications, and terms. This encompasses materials recovered through the thermo-chemical decomposition (pyrolysis) of end-of-life tires (ELTs) and other rubber components. The committee's activities are coordinated with other relevant ASTM committees to ensure comprehensive and cohesive standards.

Information on the subcommittee structure and portfolio of approved standards and ongoing Work Items is available through the List of Subcommittees, Standards, and Work Items provided by the committee. The Committee D36 aims to enhance the understanding and application of rCB in the industry, ensuring high quality and safety standards.

Existing Standards for Recovered Carbon Black (rCB)

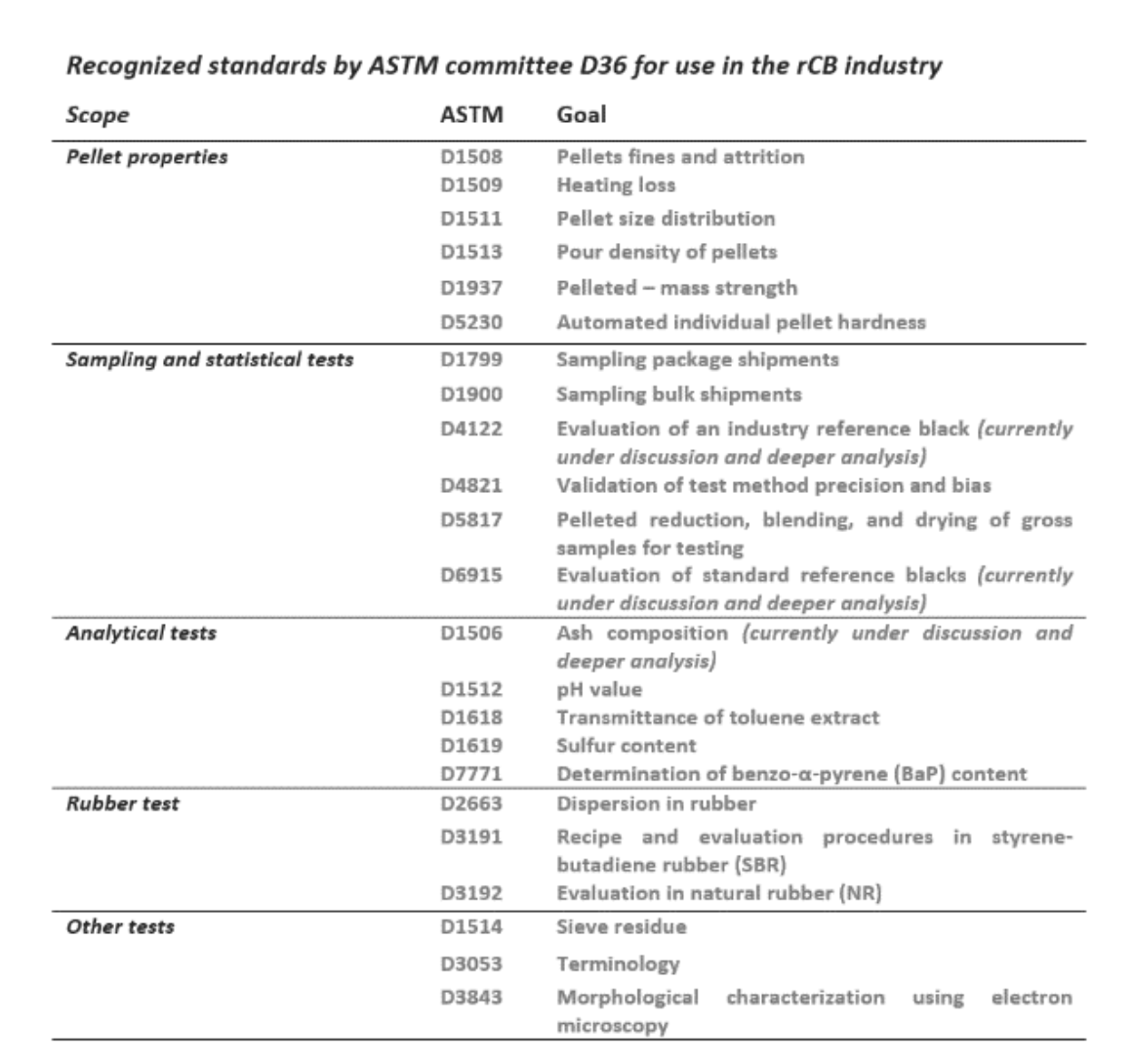

The ASTM Committee D36 on Recovered Carbon Black (rCB) has endorsed several existing standards from ASTM Committee D24 on Carbon Black for use in the rCB industry. These standards will remain in place until rCB-specific statistical data suggests the need for changes.

The committee has found that traditional carbon black characterization methods, which focus on structure level and surface area measurements, do not effectively predict the in-rubber performance of rCB products. Therefore, these methods are not recommended for evaluating rCB. However, the committee is open to new research that could alter this conclusion.

One key standard is ASTM D8178, which provides terminology for distinguishing between Char and rCB (and outlines the importance of the differences to Carbon Black as defined by the ASTM Standard D3053). It defines "recovered carbon black" (rCB) as carbon black freed from metals and fibers and processed through milling, typically imparting semi-reinforcing properties in rubber. The term "char" refers to carbonaceous residues formed during the carbonization of organic compounds.

The ASTM standard D8178 also cites existing standards related to the carbon black industry, recognized by the ASTM’s Committee D36, and maintained by Committee D24 which can be applied to the rCB industry.

ASTM Committee D36 Advances Standards for Recovered Carbon Black

The ASTM Committee D36 on Recovered Carbon Black (rCB) is progressing with several key methods, aiming to enhance the standards and practices within the industry.

One notable proposal is the "Practice for Recovered Carbon Black-Reference Compound (WK90071)" by Prof. Jorge Lacayo. This method seeks to establish a new standard for using rCB as a reference compound, which would improve the accuracy of comparisons between rCB and other rubber compounds.

Furthermore, the "Guide for Shelf Life of Recovered Carbon Black (WK73460)" has been introduced. This guide focuses on determining the shelf life of rCB to ensure its safe and efficient transport internationally. This method aims to enhance safety standards during shipping.

Additionally, the committee is updating its terminology standards with a revision to D8178-22, spearheaded by Joe Hallet. The revision includes a new definition for "Recovered Carbon Black Bound Agglomerate” addressing previous concerns and enhancing clarity in the terminology used within the industry.

These initiatives by ASTM Committee D36 underscore a commitment to improving the quality, safety, and standardization of recovered carbon black products, reflecting ongoing efforts to meet industry needs and promote best practices.

Upcoming Changes to Recovered Carbon Black Standards

Effective June 2024, significant updates will be made to the ASTM D8178-22 standard, specifically in section 3.1. A new term, "recovered carbon black bound agglomerate," will be added to clarify a key property of recovered carbon black (rCB) that impacts its application performance. The term "agglomerate" has been chosen over "particle size" to avoid confusion and describe more accurately the chemical or physical bonds in rCB.

The proposed definition describes a "recovered carbon black bound agglomerate" as the smallest separable unit of rCB, typically containing a mix of entangled carbon black aggregates and inorganic and organic impurities. The discussion around this definition highlights that bound rCB agglomerates, composed of carbon black, silica, and other substances bound by carbonaceous residue, require higher forces to break down than conventional compounding. In contrast, larger pellets formed during pelletization are held together by weaker bonds that break down more easily during compounding.

In a related update, Work Item WK89350 proposes revising D8178-22 to include a definition for "carbonaceous residue." This term refers to the carbon-rich residue formed via polymer decomposition and coking reactions during the pyrolysis of rubber goods. During pyrolysis, the organic components of rubber goods are thermally cracked and recovered predominantly as gas and oil. However, a fraction of the organic matter also cokes in situ, creating carbonaceous residue on the surface of fillers within the reactor. The amount of residue formed is highly process-dependent, making this a critical property for application performance.

Additionally, ASTM D8466 outlines various carbon black testing methods applicable to rCB, essential for both end-use applications and powder/granular-related assessments. These methods help evaluate the properties and characteristics of rCB, ensuring its suitability for specific industrial applications.

Another important test method, ASTM D8474, involves compositional analysis by thermogravimetry (TGA). This method provides a comprehensive assessment of moisture content, volatile content, organic content, and total inorganic content in rCB. Such analysis is crucial for evaluating the characteristics and quality of rCB, helping to define its grade and ensuring it meets desired quality standards. The TGA method is primarily designed for quality control and research.

Finally, ASTM D8491 evaluates the rheological non-linearity of rubber compounds using Fourier Transform Rheology (FTR). This method is essential for predicting material performance, optimizing formulations, and enhancing process efficiency in the rubber industry. It enables manufacturers to design durable and resilient products, fine-tune formulations, and innovate in material development, ultimately improving product quality and efficiency in rubber compound production.

These upcoming changes and testing methods highlight the evolving standards in the recovered carbon black industry, aimed at improving the accuracy, efficiency, and quality of rCB applications.

ASTM D36 Committee Meeting on rCB in June 2024

The ASTM D36 Committee will meet at the Philadelphia Marriott Downtown on June 12 -13, 2024. This event, led by Pieter Ter Haar, will focus on advancements and challenges in the recovered carbon black (rCB) industry. Key discussions will include particle size methods, thermogravimetric analysis, rCB applications, TPO testing methods, co-products, nomenclature, LCA guidelines, environmental sustainability, rCB sampling, and testing in rubber. The meeting will also feature strategic planning sessions to foster innovation and collaboration within the rCB community.

Summary

ASTM International, founded in 1898, develops over 12,000 voluntary consensus standards to enhance global safety, quality, and performance. Committee D36 on Recovered Carbon Black (rCB), led by Pieter Ter Haar since 2017, focuses on standards for rCB derived from end-of-life tires and other rubber components. The committee biannually works to advance knowledge, research, and develop comprehensive standards.

The ASTM Committee D36 is advancing new standards like in WK90071, which establishes a reference compound for rCB, and in WK73460, which guides the shelf life of rCB for safe transport. Revisions to D8178-22, effective June 2024, will introduce "Recovered Carbon Black Bound Agglomerate" and "carbonaceous residue."

Key testing methods include ASTM D8466 for carbon black properties, ASTM D8474 using thermogravimetry (TGA) for compositional analysis, and ASTM D8491 for evaluating rubber compounds' rheological non-linearity.

The next ASTM D36 Committee meeting in June 2024 in Philadelphia will address advancements and challenges in the rCB industry, focusing on particle size methods, thermogravimetric analysis, applications, testing methods, sustainability, and strategic planning to improve rCB quality and safety.

Recognized standards by ASTM committee D36 for use in the rCB industry. | Image by ASTM International.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.