Weibold Academy: End-of-life tires pyrolysis research boom

Weibold Academy article series discusses periodically the practical developments and scientific research findings in the end-of-life tire (ELT) recycling and pyrolysis industry.

These articles are reviews by Claus Lamer – the senior pyrolysis consultant at Weibold. One of the goals of the review is to give entrepreneurs in this industry, project initiators, investors and the public, a better insight into a rapidly growing circular economy. At the same time, this article series should also be a stimulus for discussion.

For completeness, we would like to emphasize that these articles are no legal advice from Weibold or the author. Please refer to the responsible authorities and specialist lawyers for legally binding statements.

Introduction

For years, discarded tires have posed a serious environmental dilemma. Their resilience makes it challenging to break them down while burning them releases harmful pollutants. Researchers have increasingly turned to pyrolysis, a thermal process that transforms waste tires into valuable products such as pyrolysis oil, recovered carbon black (rCB), and gas.

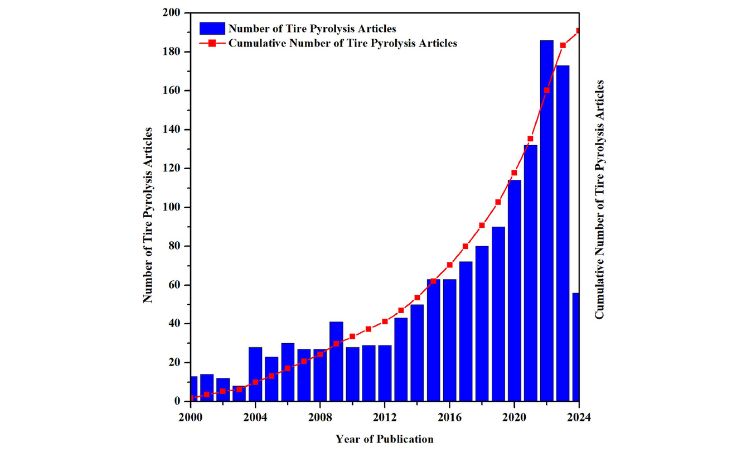

Over the past 20 years, interest in tire pyrolysis has surged dramatically. A recent analysis of more than 1,400 studies published between 2000 and 2024 shows that research in this field has accelerated, particularly since 2016. Countries like China and India have emerged as major contributors, driven by growing environmental concerns and the need for sustainable waste management solutions. Scientists are primarily focused on refining pyrolysis techniques to improve efficiency, enhance product quality, and scale up for industrial applications.

The Growth of Pyrolysis Research

The number of studies dedicated to tire pyrolysis has increased significantly, reflecting a shift toward sustainable waste treatment. In 2000, research output was minimal, but by 2024, over 1,400 publications had emerged. This trend aligns with stricter environmental policies worldwide, such as the European Union's restrictions on tire landfilling and China’s investment in alternative waste processing technologies.

Researchers are especially interested in three key areas: co-pyrolysis, pyrolysis oil refinement, and rCB purification. These areas are crucial for maximizing tire pyrolysis's potential and ensuring commercial viability.

Source: https://doi.org/10.1016/j.cles.2025.100181

Advancements in Co-Pyrolysis

Conventional pyrolysis involves processing tires alone, but co-pyrolysis—combining tires with other materials like biomass or plastics—has shown promising results. Studies indicate that this method increases bio-oil production and improves gas yields.

Microwave-assisted co-pyrolysis is one innovation that has improved process efficiency. Researchers have achieved better heating distribution and higher-quality outputs using carbon black as a microwave absorber. In addition, chemical activators like ZnCl₂ and KOH have been used to improve gas and liquid yields, making the process more viable on a larger scale.

However, co-pyrolysis presents challenges. Uneven heating across different materials and difficulties scaling up microwave-assisted processes remain barriers to industrial application. Nonetheless, advances in catalytic co-pyrolysis suggest that this method could soon be optimized for large-scale operations.

Improving Pyrolysis Oil for Fuel Applications

One of the most promising byproducts of tire pyrolysis is pyrolysis oil, which has potential as an alternative fuel. However, its high sulfur content and presence of polycyclic aromatic hydrocarbons (PAHs) limit its usability without further refining.

Researchers have developed hydrotreatment and oxidative desulfurization (ODS) techniques to improve its quality. Studies show that catalysts like Co/SBA-15 and nitrogen-doped biochar can remove up to 99% sulfur, making the oil cleaner and more stable. Additionally, ultrasound-assisted solvent extraction has shown effectiveness in reducing PAH content.

Despite these advancements, challenges remain. Refining pyrolysis oil is still costly, and some methods require toxic solvents. More research is needed to develop cost-effective, scalable solutions that make pyrolysis oil a competitive fuel alternative.

Refining Recovered Carbon Black for Reuse

Another valuable product of tire pyrolysis is recovered carbon black (rCB), a material used in manufacturing tires, pigments, and adsorbents. However, impurities such as residual ash and bound rubber have limited usability.

Recent advancements in acid-based demineralization and physical activation have improved rCB quality, making it a more viable substitute for virgin carbon black. A ual-acid treatment using hydrochloric acid and phosphate fertilizer acidd has reduced ash content by over 98%. At the same time, CO₂ activation at high temperatures has increased its surface area, making it useful for water purification and energy storage applications.

While these methods improve rCB’s properties, scalability and cost remain challenges. Acid treatments generate hazardous waste, and high-temperature activation requires substantial energy. However, as researchers refine these techniques, rCB is expected to play a more significant role in the circular economy.

Scaling Up for Industrial Use

Although tire pyrolysis research has led to substantial technological progress, commercial adoption remains relatively slow. High initial costs, energy-intensive processes, and regulatory challenges pose challenges to large-scale implementation. Many of the most effective refining methods remain confined to laboratory settings.

However, the last two decades of research have highlighted pyrolysis as a viable solution for managing tire waste. If adequately scaled, this process could turn waste tires into valuable resources, helping reduce environmental pollution while creating sustainable alternatives to fossil fuels and virgin raw materials. Continued investments in integration, harmonization, and scaling of the technologies slowly enable the maturing industry to overcome the barriers to broad adaptation.

Conclusion

The exponential growth in tire pyrolysis research over the past two decades signifies a broader commitment to sustainability and resource recovery. Scientists have made significant strides in optimizing co-pyrolysis, refining pyrolysis oil, and enhancing recovered carbon black, making these processes more viable for large-scale industrial applications. However, challenges related to cost, scalability, and environmental impact remain obstacles to widespread adoption.

The road ahead for tire pyrolysis involves continued innovation, government incentives, and industry collaboration. With proper support and advancements, pyrolysis will play a key role in sustainable waste management and circular economy initiatives. The real challenge is bridging the gap between research and industrial implementation, ensuring that these innovations translate into real-world solutions addressing environmental and economic concerns.

Source

Zaki Siti Nuramirah Rabbani Muhammad Zaki, Zainal Nurul Fatahah Asyqin, Chay Tay Chia, GLOBAL TRENDS OF WASTE TIRE PYROLYSIS RESEARCH: A BIBLIOMETRIC ANALYSIS, Cleaner Energy Systems (2025), doi: https://doi.org/10.1016/j.cles.2025.100181

According to Elsevier's CC BY (Creative Commons Attribution) policy, this research is published under an Open Access license. This license allows users to read, download, distribute, and reuse the article with appropriate attribution to the original authors and source.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.