Weibold Academy: Chemical Recycling of End-of-life Tires – a contribution to achieve SDGs

Weibold Academy article series discusses periodically the practical developments and scientific research findings in the end-of-life tire (ELT) recycling and pyrolysis industry.

This article is a review by Claus Lamer – the senior pyrolysis consultant at Weibold. One of the goals of this review is to give entrepreneurs in this industry, project initiators, investors and the public, a better insight into a rapidly growing circular economy. At the same time, this article series should also be a stimulus for discussion.

For the sake of completeness, we would like to emphasize that these articles are no legal advice from Weibold or the author. For legally binding statements, please refer to the responsible authorities and / or specialist lawyers.

Source: United in Diversity Creative Campus (2016).

Introduction

Since their launch in 2015, the 17 Sustainable Development Goals (SDGs) and the 169 timebound targets underpinning them have provided all stakeholders – the private sector included – with a lens through which to translate global needs and ambitions into business solutions. Companies and sectors that apply their creativity and innovation to develop these solutions will be able to better manage risks, anticipate consumer demand, capture growth markets, and strengthen supply chains in line with the sustainability needs outlined by the SDGs.

Formed in 2005, the World Business Council for Sustainable Development’s (WBCSD) Tire Industry Project (TIP) is the primary global forum for the tire industry on sustainability issues. TIP’s mission is to proactively identify and study the potential human health and environmental impacts associated with the life cycle impacts of tires to contribute to a more sustainable future. With a membership of 11 leading tire manufacturers representing more than 60% of global tire manufacturing capacity, TIP is well positioned and has developed an SDG roadmap for the tire industry as a resource for the entire sector to leverage.

The tire industry basically interacts with all 17 SDGs; However, the SDG roadmap for the tire industry focuses on areas where the sector has the greatest potential to lead, influence and accelerate action to make progress towards the 2030 Agenda. As such, eight SDGs have been identified as priorities, with SDG 8 (decent work and economic growth) and 12 (responsible consumption and production) being most frequently cited by the roadmap measures.

Megatrends

Despite continued sustainability progress, megatrends (trends that influence a global scale) encompassing significant environmental, social, economic, or technological changes have the potential to disrupt business and society as a whole and will likely continue to do so for decades to come. Of the key megatrends presenting significant challenges for the business community, four are particularly relevant to the tire sector within the wider context of sustainable development:

- Circular innovation to tackle resource scarcity

- Climate and nature crises to accelerate the low-carbon energy transition

- Industry 4.0 to allow systems transformation

- Human rights, safety, well-being, and equal opportunities – across the value chain – are essential to building resilience.

A growing population and increasing urbanization worldwide are promoting an increase in mobility. At the same time, however, the resource challenges (resulting from the growing demand) associated with a growing population and increasing urbanization promoted worldwide also offer the opportunity and necessity for the emergence of new business models based on the circular economy.

Global trends converge and form concrete new opportunities and markets. Global consumer sustainability awareness is driving policies from the United Nations (Sustainable Development Goals, SDGs) on to state and local governments. Most of all, the industrial giants of all industry sectors are tightening their Corporate Sustainability Goals (CSGs) for a climate-neutral future. As a result, demand for high-grade tire-derived raw materials as an alternative to their virgin counterparts is experiencing a phenomenal upswing. In a nutshell, it can be stated that the demand for high-grade tire-derived raw materials (recovered Carbon Black and tire-derived-oil (TDO)) far exceeds the supply.

Concurrently, large investments in research, development and refinement of the core technologies have resulted in breakthroughs of some candidates in the chemical end-of-life tire recycling (ELT pyrolysis) for rapid scaling to industrial-scale suppliers.

The promise of ELT pyrolysis in tire circularity

The chemical recycling of end-of-life tires (ELT) through pyrolysis is a recycling operation by which waste materials (ELTs) are reprocessed into chemical products (recovered Carbon Black and tire-derived-oil (TDO)) to become input feedstock for chemical plants. (ECHA, 2021; US EPA, 2021)

Chemical recyclers / up-cyclers that process end-of-life tires using pyrolysis are manufacturers of environmentally sustainable chemical feedstocks for the chemical and rubber industry. State-of-the-art pyrolysis technologies do not only avoid greenhouse gas emissions compared to today’s conventional production processes, but also increases the resource efficiency while closing the loop in the transition to a circular economy.

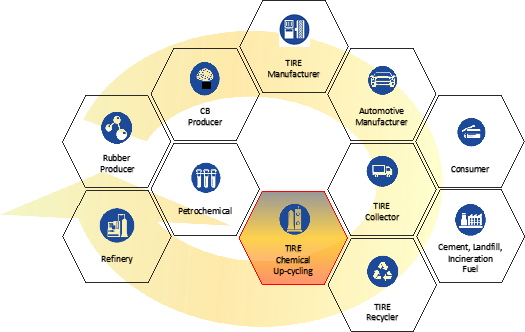

Figure: The missing link to tire circularity ((c) Weibold, 2022; published in Rubber World, September 2022).

Recent life cycle analysis (LCA) indicates tremendous positive environmental impact and significant savings in resources, CO2 emissions, water, and electricity use. Although these analytic results by a wide range of suppliers vary, we can show objectively that one can safely assume that the chemical recycling of ELTs through pyrolysis eliminates between 3 and 4 tons of direct and indirect CO2 emissions compared to today’s conventional production processes.

The materials produced in tire pyrolysis operations are thus becoming of great value to the stakeholders in the tire upstream and downstream value chains. Pyrolysis therefore incorporates the promise of closing the loop between the ELT waste stream and the tire manufacturing process.

Contribution to achieving SDG 8 and 12

Chemical recyclers / up-cyclers that process end-of-life tires using state-of-the-art pyrolysis technologies are significantly contributing to achieving decent work and economic growth (SDG 8) and responsible consumption and production (SDG 12).

- SDG 8.4: They are gradually improving global consumption and production in terms of resource efficiency and helping to decouple economic growth from environmental degradation.

- SDG 12.2: They promote the sustainable management and efficient use of natural resources.

- SDG 12.4: They make a significant contribution to the environmentally friendly management (substitution) of chemicals. Reduce waste generation throughout the tire lifecycle, thereby significantly minimizing releases to air, water and soil and associated adverse impacts on human health and the environment.

- SDG 12.4: Chemical recycling significantly reduces waste as the recovered materials can be reused without compromising the quality of the product.

- SDG 12.6: They encourage companies, particularly large and transnational corporations, to adopt sustainable practices and integrate sustainability information into their reporting cycle.

- SDG 12.8: They help people everywhere to develop awareness of this sustainable development in the waste tire sector and (also as private individuals) to ensure that their ELTs are "disposed of" in an environmentally friendly and sustainable manner (i.e., no illegal waste dumps).

Figure: Priority SDGs for the tire industry sector (WBCSD TIP).

Chemical recyclers / up-cyclers indirectly also support the achievement of other SDGs, most notably SDG 11 (sustainable cities and communities) and SDG 15 (life on land).

Conclusion

The 2030 Agenda for Sustainable Development, adopted by all United Nations Member States in 2015, provides a shared blueprint for peace and prosperity for people and the planet, now and into the future. At its heart are the 17 Sustainable Development Goals (SDGs), which are an urgent call for action by all countries - developed and developing - in a global partnership. They recognize that ending poverty and other deprivations must go together with strategies that improve health and education, reduce inequality, and spur economic growth – all while tackling climate change and working to preserve our oceans and forests.

The tire industry basically interacts with all 17 SDGs; However, the SDG roadmap for the tire industry focuses on areas where the sector has the greatest potential to lead, influence and accelerate action to make progress towards the 2030 Agenda.

The tire industry is increasingly supporting the use of chemicals produced by chemical recyclers using state-of-the-art pyrolysis of ELTs presenting the opportunity to reduce the tire industry’s reliance on petrochemicals by i.e., replacing a portion of traditional carbon black with a sustainable and circular alterative without introducing performance trade-offs.

It can be shown that chemical recyclers of end-of-life tires (ELT) make a major contribution to achieving the Sustainable Development Goals, specifically SDG 8 (decent work and economic growth) and 12 (responsible consumption and production).

In summary we can categorically conclude that, since operations of state-of-the-art chemical tire recycling (pyrolysis) plants are producing sustainable chemical feedstocks, they thereby support the overarching and concrete specified goals of the EU Green New Deal as well as the UN Sustainable Development Goals and significantly contribute to the GHG reductions in the manufacture of carbon black and base chemicals.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.