Ecolomondo begins installation of new milling line to enhance rCB production

Ecolomondo Corporation (TSXV: ECM) (OTCQB: ECLMF) is pleased to announce that it has received and began the installation of its new milling line, as planned.

The Company recently received the delivery of its new milling line purchased in August 2024. The Company has been preparing for the installation of the new milling line for several months to ensure its installation would be as seamless as possible. Once installed, this new milling line will be fully automated using HMI technology. As previously announced, the milling line is expected to have a capacity to process 2,200 lbs per hour of recovered carbon black (rCB) with a particle size distribution of 90% between 10-15 microns, specifications required by most of the Hawkesbury plant’s rCB off-take customers.

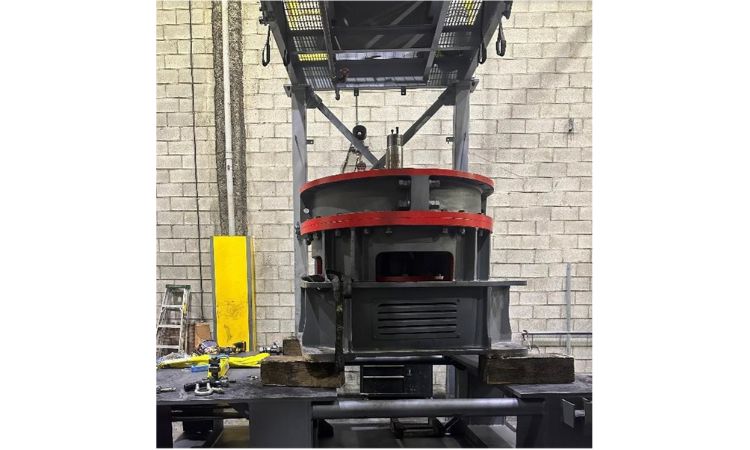

Picture of the new grinding mill being installed. | Photo by Ecolomondo Corporation.

The processing capacity of the new milling line should more than satisfy the production capacity of rCB produced at the Hawkesbury plant. Achieving this milestone and commissioning the new milling line are very important to reaching full commercialization, because rCB is the main revenue driver of the Hawkesbury plant.

Commissioning of the new milling line is expected to begin in March 2025 with initial rCB milling production expected to begin in May 2025, gradually ramping-up to full production by late in the fourth quarter of 2025.

While the Hawkesbury facility was waiting for the new milling line, operations and efficiency were aggressively increased, always working towards full optimization. In 2024, the Company increased the shredding capacity and processed over 1,200 metric tons of scrap tires, ran 78 TDP batches at full capacity of 15,000 lbs, shipped approximately 1,800 barrels of tire-derived oil (13 tanker loads of 145 barrels), and sold 138 metric tons of steel. The Hawkesbury facility also produced approximately 200 metric tons of rCB, now waiting to be processed by the new milling line.

The output from the Hawkesbury facility confirms the robustness of the equipment, the safety and efficiency of the process, the efficiency of the control system, and the quality and consistency of the end-products.

Press release by Ecolomondo Corporation.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.