Mars Mineral signed Memorandum of Understanding with South Korean-based LD Carbon

Mars Mineral, a global provider of pelletizing technology equipment, has entered into a memorandum of understanding (MOU) with South Korean-based LD Carbon to develop and install Mars’ pin mixer technology at LD Carbon’s newest pyrolysis and recovered carbon black (rCB) facility.

LD Carbon is a material industry company that supplies its Green Carbon Black, an eco-friendly rCB made from waste tires that have been pyrolyzed, refined, and processed for reuse by tire and rubber manufacturers. LD Carbon also reclaims pyrolysis oil from the process that is used for replacing crude oil and raw material of petrochemical products.

According to the Tire Industry Project for the World Business Council, four billion waste tires are in landfills and stockpiles worldwide, causing soil and water pollution. In addition, many are burned as fuel, causing serious air pollution and carbon emissions. End-of-life tire (ELT) pyrolysis, along with other methods, mitigates environmental risks.

Mars Mineral pin mixer equipment takes the fine pyrolyzed char from ELTs and pelletizes it in the presence of a binder, usually water. The resulting dried rCB pellets are easier to package and transport to end-users in the rubber, plastics, and paint and coatings industries. “Pelletizing is vital to moving the output from a pyrolysis plant to their customers. It is an important link in material circularity strategies, which derive value from unrecovered post consumer materials like ELTs. We welcome this opportunity with such an ecologically progressive company as LD Carbon,” said Clayton Woodward, Mars Mineral CEO.

“In early 2024, it’s projected that LD Carbon’s rCB production capacity will reach 16 kilotons annually. We believe LD Carbon can bring quality rCB in pelletized form to key customers in tire and rubber industries by incorporating Mars Mineral’s technology,” said Bumseek Kim (BK), LD Carbon CCO.

About Mars Mineral

Mars Mineral is in Mars, Pa., 25 miles north of Pittsburgh. The company manufactures pin mixers, disc pelletizers, and deep drum pelletizers. This technology has become the centerpiece of many companies’ industrial processes and sustainability initiatives. It converts toxic fines or dust into pellets that can be easily bagged, transported, and marketed, such as rCB from ELTs. Mars Mineral also provides material testing and engineering and technical support.

About LD Carbon

LD Carbon was established in 2017. The company produces rCB and pyrolysis oil from the pyrolysis of waste tires and supplies it to tire and rubber product manufacturers. The company recently signed an MOU with Sumitomo Rubber Industries Ltd. to jointly commercialize rCB and pyrolysis oil. LD Carbon’s rCB is currently commercialized by Hankook Tire and is being tested by several top 10 global tire makers. Since 2023, LD Carbon has successfully secured nearly 50 million USD in funding and will have a new pyrolysis and rCB manufacturing plant with an ELT capacity of 50 kilotons annually, opening in Dangjin, South Korea, by the first quarter of 2024.

About Pin Mixer Technology

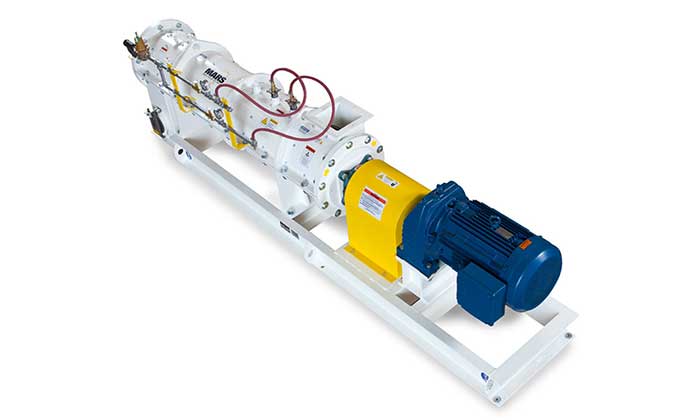

Image by Mars Mineral.

Mars Mineral Pin Mixer micro-pelletizes, agglomerates, or conditions powdered materials, such as carbon black, tire char, cement kiln dust, manure, pigments, coal dust, pesticides, electric furnace baghouse dust, limestone fines, graphite, coke, petroleum coke fines, and bauxite and silica fume for further processing in a pelletizer.

The material enters at one end of the cylinder and is whipped by the pins as it moves from the inlet, through the shell, and to the bottom outlet. Fine mixing and micro-agglomeration will occur as a fine spray of liquid is added at the entry section and distributed throughout the powder. The result is a wetted, agglomerated, and densified micro-pellet. Learn more at https://www.marsmineral.com/pin-mixer.php.

Press release by Mars Mineral.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.