Zeppelin Systems introduces innovative process and collaborative approach in tire recycling

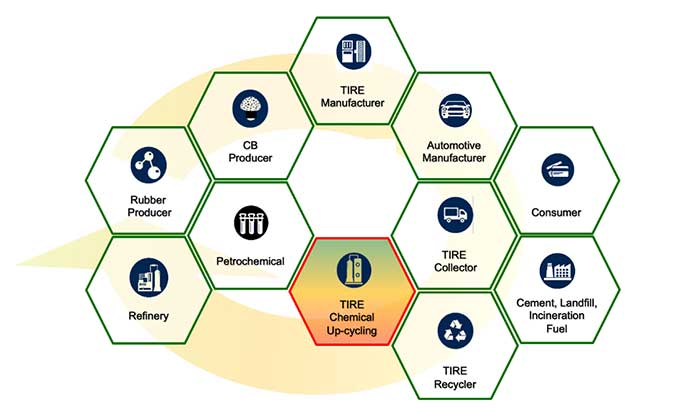

In his recent article, Patrick Buder, Sustainability Strategy Manager at Zeppelin Systems GmbH, explains the company's approach to sustainable end-of-life tire recycling. Zeppelin Systems has been working with the tire industry for over 40 years and aims to achieve efficient material handling and environmentally friendly operations through their solution architecture. They have developed a new process in collaboration with project partners from various industrial sectors to create high-quality recyclates that can be reintroduced into the material cycle.