Tyromer CEO Jon Visaisouk discusses devulcanization strategy on Tyre Recycling Podcast

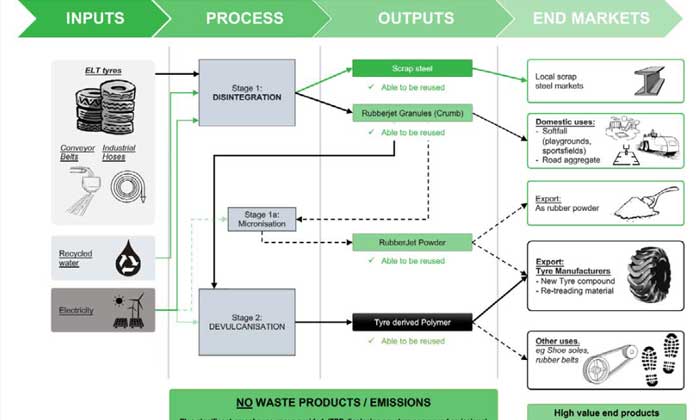

Jon Visaisouk, CEO of Tyromer, appeared on Episode 79 of The Tyre Recycling Podcast, recorded live at the Round Trip Tyre and Conveyor Belt Recycling Summit in Melbourne. Tyromer employs a proprietary devulcanization process to convert crumb rubber into high-value material for new rubber manufacturing. During the interview, Visaisouk discussed the company's transition following the passing of founder Sam Visaisouk, operational progress at Tyromer's European facility in Arnhem, Netherlands, and increasing adoption of devulcanized rubber products, particularly from Tyromer India's production operations.